Solutions pour l'excellence opérationnelle

Un écosystème digital dédié à la performance industrielle

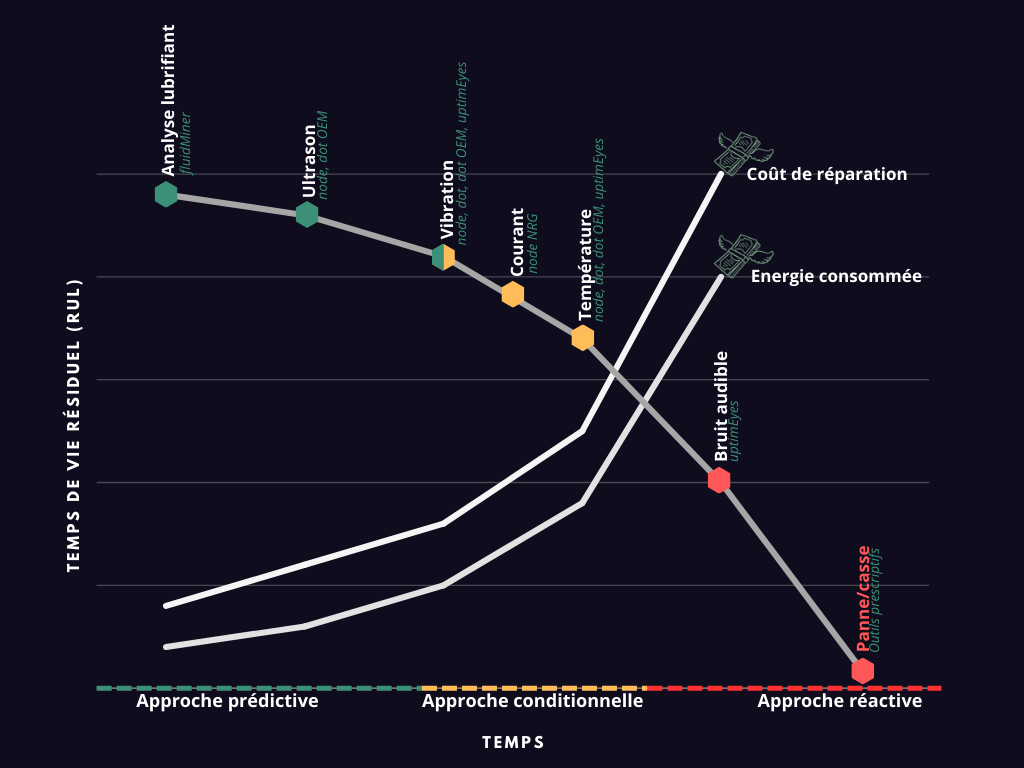

Vous permettre de suivre et d’anticiper le cycle de vie de vos machines, à travers des données pertinentes est notre rôle au quotidien. Notre engagement : contribuer à construire une usine du future plus fiable et plus efficace.

Nous sommes

catalyseurs de leur

performance industrielle.